Ahead-looking: A group of Australian researchers has unveiled a breakthrough methodology for extracting gold that might dramatically cut back the environmental and well being hazards lengthy related to mining and digital waste recycling. The innovation, developed at Flinders College, gives a safer and extra sustainable various to the usage of poisonous chemical substances like mercury and cyanide, which have traditionally dominated the gold restoration trade.

Gold, prized for its rarity and flexibility, is important not just for jewellery and funding but additionally for its position in electronics, medication, and aerospace. Nonetheless, conventional extraction strategies come at a excessive value. Cyanide and mercury, generally used to separate gold from ore, pose important threats to ecosystems and human well being. Mercury, particularly, is broadly utilized by small-scale miners worldwide, typically leading to extreme mercury poisoning and environmental contamination.

The worldwide surge in digital waste underscores the urgency for change. In 2022 alone, the world generated an estimated 62 million tonnes of e-waste, a lot of it containing invaluable metals like gold. But, lower than 1 / 4 of this waste was formally collected and recycled, leaving hazardous supplies to build up in landfills or be processed underneath unsafe circumstances.

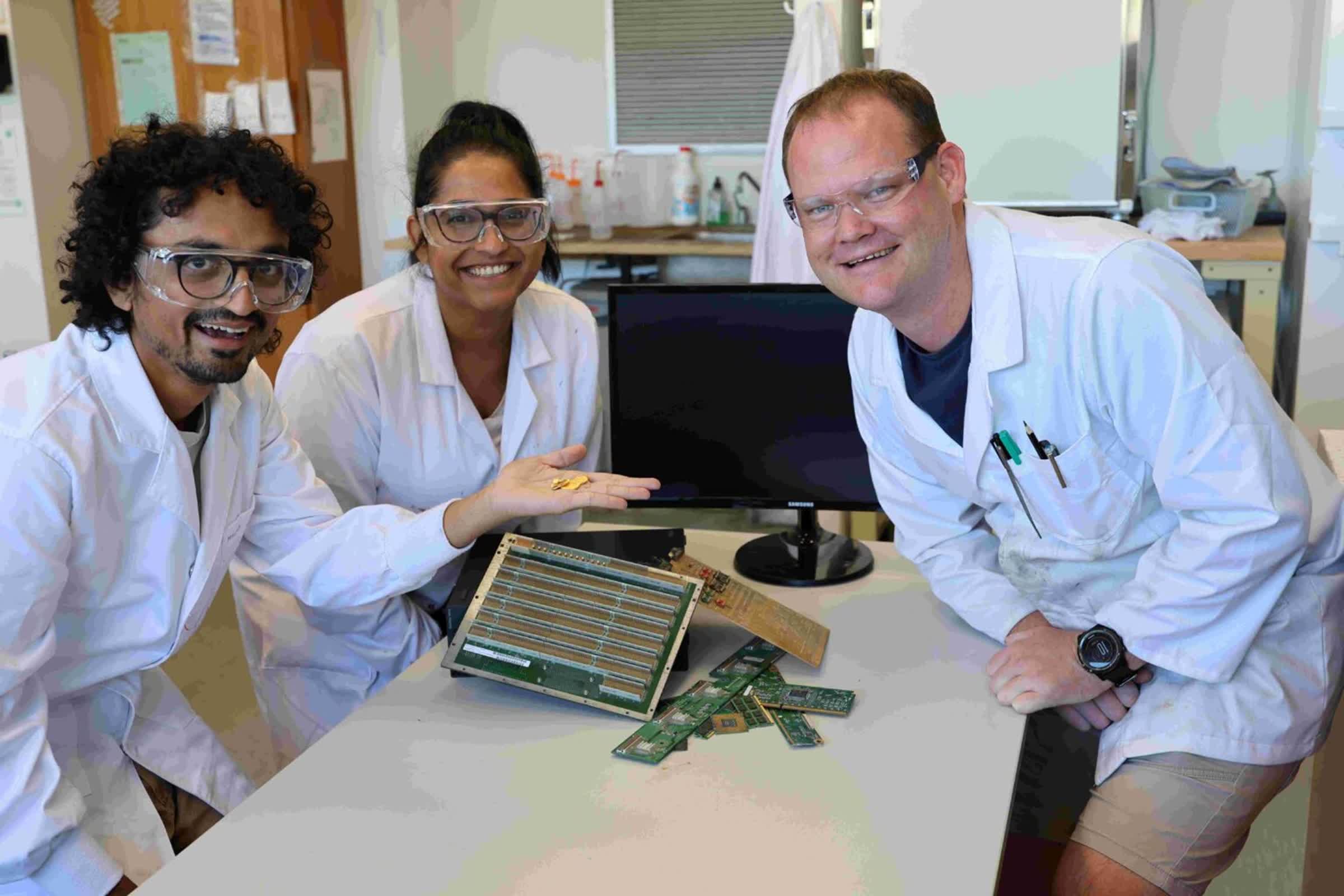

Led by Professor Justin Chalker, the Flinders College group has developed an extraction course of that replaces hazardous chemical substances with a compound generally used for water disinfection. This reagent, when mixed with salt water, can dissolve gold from ore or digital waste. The dissolved gold is then captured by a specifically designed, sulfur-rich polymer that selectively binds to the dear metallic, even in complicated mixtures.

What units this methodology aside is its recyclability. As soon as the gold is collected, the polymer will be triggered to interrupt down, releasing the gold and permitting the polymer to be reused. This closed-loop strategy not solely minimizes waste but additionally reduces the necessity for brand spanking new uncooked supplies.

The analysis, revealed within the journal Nature Sustainability, demonstrates that the approach is efficient on a variety of supplies, from mining ore to discarded laptop parts. The group collaborated with specialists in america and Peru to validate the tactic in numerous contexts, together with small-scale mining operations that sometimes depend on mercury.

By collaborating with trade companions, the researchers intention to scale up the method and supply a sensible resolution for each the mining and e-waste recycling sectors. Their work not solely addresses the urgent subject of e-waste administration but additionally factors towards a future the place invaluable assets will be recovered with out compromising environmental or human well being.