Ahead-looking: A brand new chapter in supplies science is unfolding at MIT, the place researchers have developed a completely autonomous robotic system designed to speed up the seek for superior semiconductors. This expertise goals to handle a long-standing problem: the sluggish tempo of manually measuring key properties in new supplies, which has restricted progress in fields similar to photo voltaic vitality.

On the coronary heart of the system is a robotic probe able to measuring photoconductance, a property that reveals how a fabric responds to gentle. By integrating professional information from supplies scientists right into a machine-learning mannequin, the robotic can decide probably the most informative factors to probe on a pattern. This method, paired with a specialised planning algorithm, permits the robotic to maneuver shortly and effectively between contact factors.

In a rigorous 24-hour take a look at, the robotic carried out greater than 125 distinctive measurements per hour, surpassing the precision and reliability of earlier synthetic intelligence-based strategies. This leap in pace and accuracy might speed up the event of extra environment friendly photo voltaic panels and different digital gadgets.

“I discover this paper to be extremely thrilling as a result of it gives a pathway for autonomous, contact-based characterization strategies,” stated Tonio Buonassisi, a professor of mechanical engineering and senior writer of the research. “Not each necessary property of a fabric will be measured in a contactless means. If you could make contact together with your pattern, you need it to be quick and also you wish to maximize the quantity of knowledge that you simply acquire.”

The analysis crew, led by graduate pupil Alexander Siemenn, together with postdoctoral researchers Basita Das and Kangyu Ji, in addition to graduate pupil Fang Sheng, revealed their findings in Science Advances.

The journey towards this innovation started in 2018, when Buonassisi’s lab got down to construct a completely autonomous supplies discovery laboratory. The efforts have lately targeted on perovskites, a category of semiconductors utilized in photo voltaic panels. Whereas earlier advances allowed for fast synthesis and imaging-based evaluation, precisely measuring photoconductance nonetheless required direct contact with the fabric.

“To permit our experimental laboratory to function as shortly and precisely as potential, we needed to give you an answer that will produce one of the best measurements whereas minimizing the time it takes to run the entire process,” Siemenn defined.

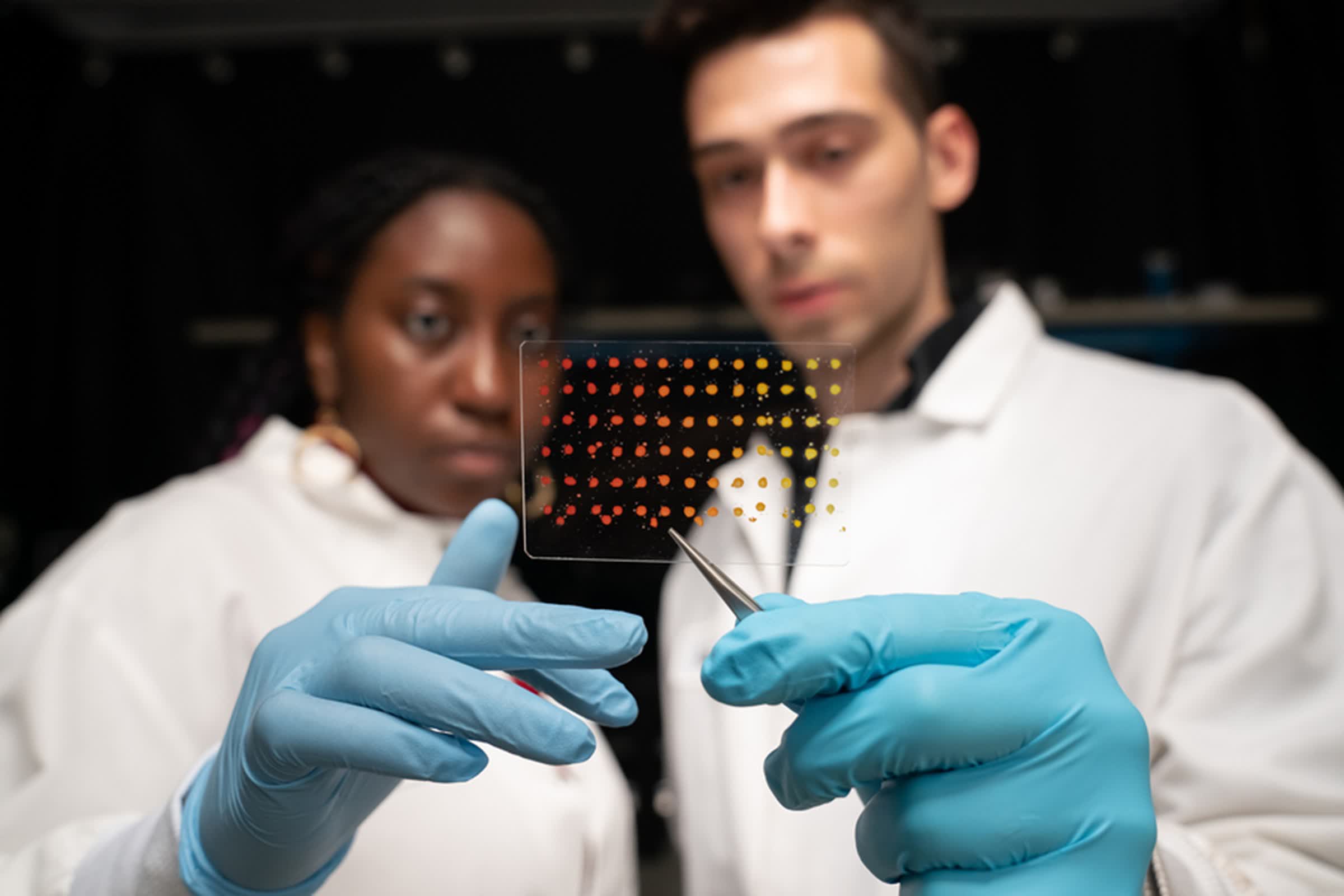

The system begins by capturing a picture of the perovskite pattern utilizing its onboard digicam. Pc imaginative and prescient then divides the picture into segments, that are analyzed by a neural community mannequin that includes the experience of chemists and supplies scientists. “These robots can enhance the repeatability and precision of our operations, however you will need to nonetheless have a human within the loop. If we do not have a great way to implement the wealthy information from these chemical consultants into our robots, we’re not going to have the ability to uncover new supplies,” Siemenn added.

The neural community identifies one of the best probe contact factors based mostly on the pattern’s form and composition. These factors are then fed right into a path planner that determines probably the most environment friendly route for the robotic to observe. The adaptability of this method is essential, because the samples typically have distinctive shapes. “It’s virtually like measuring snowflakes – it’s troublesome to get two which are an identical,” Buonassisi stated.

A key innovation is the self-supervised nature of the neural community, which selects optimum contact factors instantly from pattern photographs while not having labeled coaching knowledge. The crew additionally improved the trail planning algorithm by introducing a small quantity of randomness, which helped the robotic discover shorter paths.

“As we progress on this age of autonomous labs, you actually do want all three of those experience – {hardware} constructing, software program, and an understanding of supplies science – coming collectively into the identical crew to have the ability to innovate shortly. And that’s a part of the key sauce right here,” Buonassisi stated.

After constructing the system, the researchers examined every element. The neural community outperformed seven different AI-based strategies in figuring out contact factors with lowered computation time, and the trail planner constantly generated shorter routes than competing algorithms. In a full 24-hour autonomous experiment, the robotic accomplished over 3,000 photoconductance measurements, figuring out each high-performing areas and areas of degradation within the supplies.

“With the ability to collect such wealthy knowledge that may be captured at such quick charges, with out the necessity for human steering, begins to open up doorways to have the ability to uncover and develop new high-performance semiconductors, particularly for sustainability purposes like photo voltaic panels,” Siemenn stated.

Wanting forward, the crew plans to refine the system additional as it really works towards establishing a completely autonomous laboratory for supplies discovery. The venture is supported by organizations together with First Photo voltaic, Eni via the MIT Vitality Initiative, MathWorks, the College of Toronto’s Acceleration Consortium, the US Division of Vitality, and the US Nationwide Science Basis.